Post war Škoda cars

Basic Classification of Vehicles

Layman’s Overview

Right after the war: Rapid – assembled from pre-war spare parts.

Post-war years: Tudor (1101–1102).

1950s: 1200–1201, Spartak (Š440–445), convertible from Spartak (450).

1960s: Octavia, Felicia, 1000 MB, 1202 STW.

1970s: 100, 110 R (coupé).

1980s: 105–130 Rapid, Favorit.

1990s: Felicia, Octavia.

Detailed Overview

Smaller range:

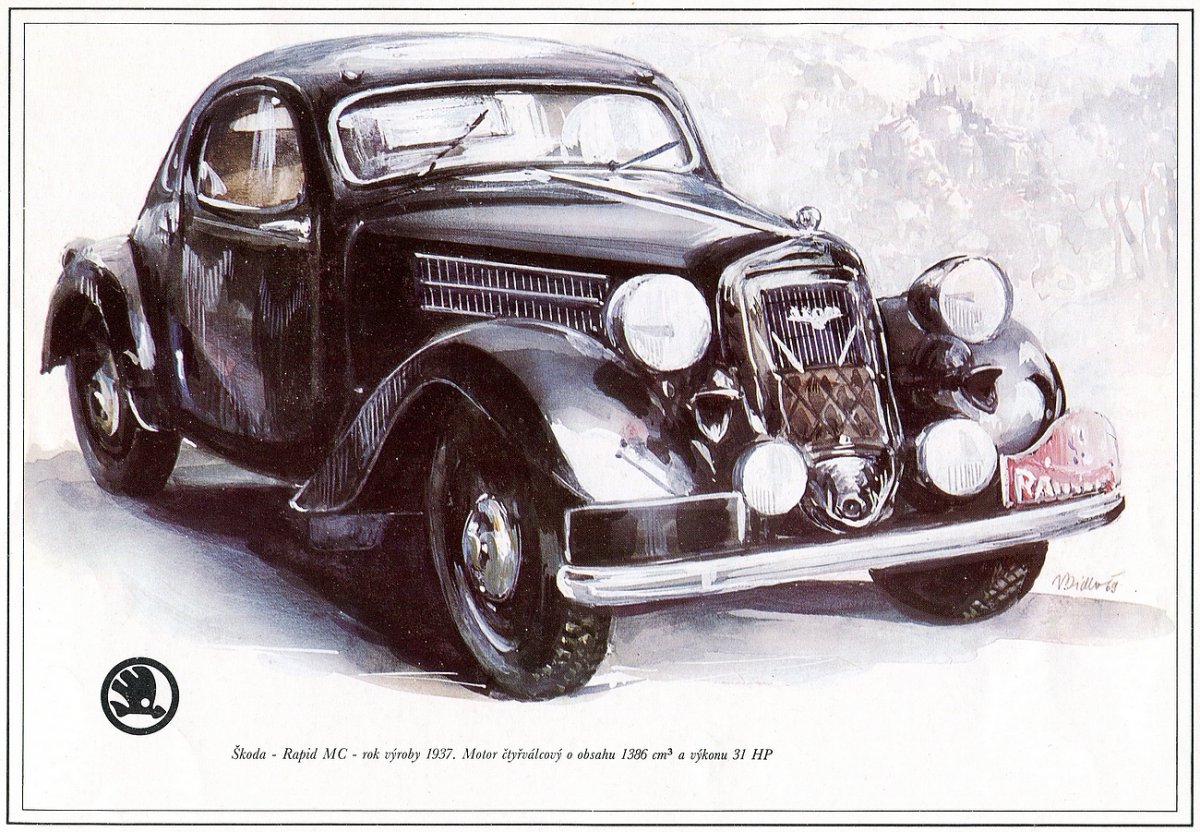

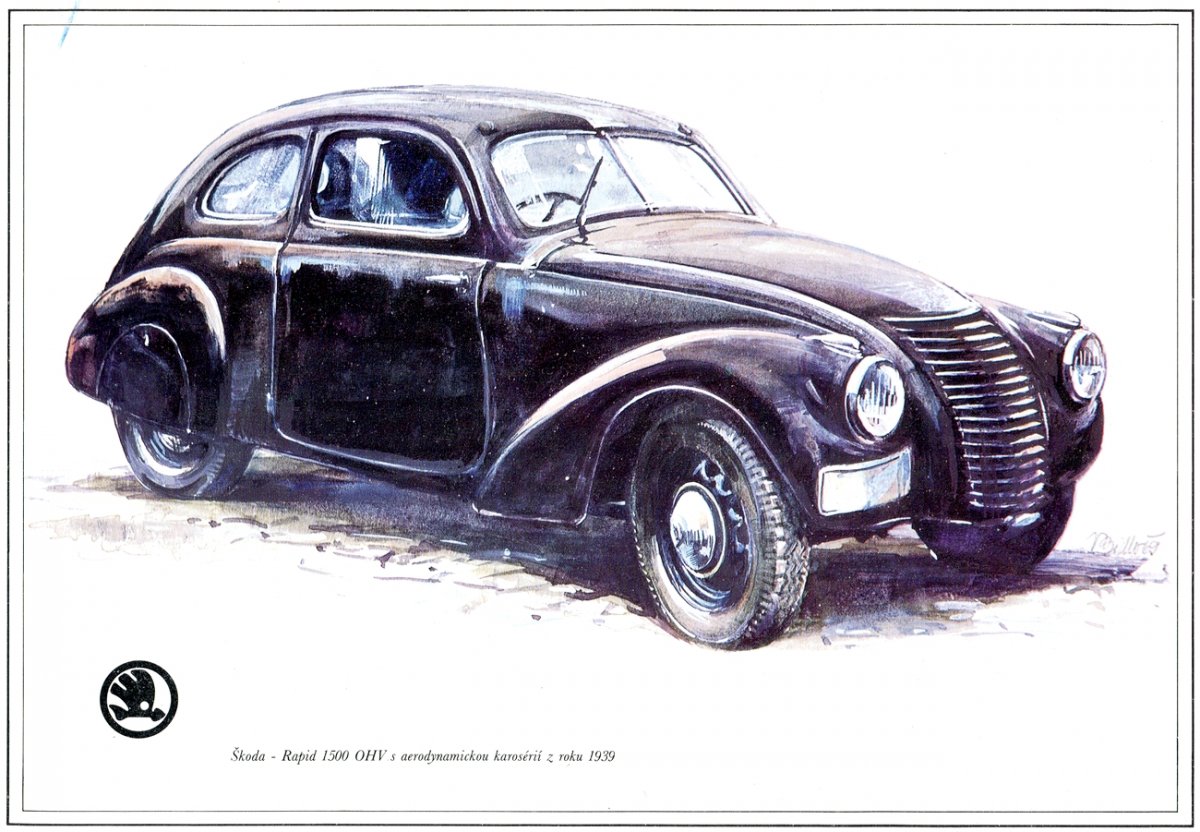

ŠKODA Rapid (1934–1945)

ŠKODA 1101 (1946–1949)

ŠKODA 1102 (1949–1952)

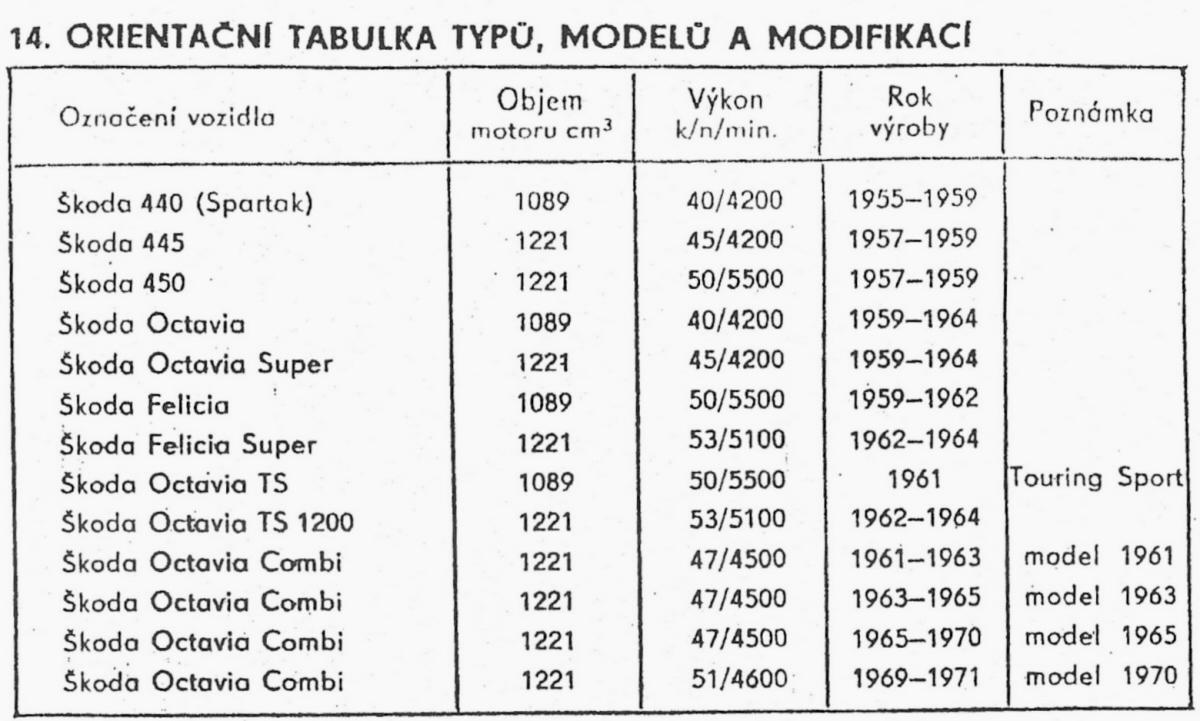

ŠKODA 440 “Spartak” (1955–1959)

ŠKODA 445 “Spartak 45 PS” (1957–1959)

ŠKODA 450 (convertible) (1957–1959)

ŠKODA Octavia (no fins, 1959–1960)

ŠKODA Octavia (with fins, 1961–1964)

ŠKODA Octavia Super

ŠKODA Felicia (1959–1964)

ŠKODA Felicia Super (1961–1964)

ŠKODA Octavia Combi (1961–1971)

ŠKODA 1000 MB (1964–1969)

ŠKODA 1000 MB De Luxe (1966–1969)

ŠKODA 1000 MBG (1966–1969)

ŠKODA 1100 MB De Luxe (1967–1969)

ŠKODA 1100 MBX De Luxe (1967–1969)

ŠKODA 100, 100L, 110L (1969–1977)

ŠKODA 110 LS (1971–1976)

ŠKODA 110 R (1970–1980)

ŠKODA 105, 120 (1976–1987)

ŠKODA Garde (1983–)

ŠKODA 130 (1984–)

ŠKODA Favorit (1988–)

ŠKODA Forman, Pickup (1991–)

ŠKODA Felicia (1994–)

ŠKODA Felicia Combi, Pickup (1995–)

ŠKODA Felicia Fun (1997–)

ŠKODA Octavia (1996–)

Larger range:

ŠKODA 1200 (1952–1956)

ŠKODA 1201 (1955–1961)

ŠKODA 1202 STW (1961–1973)

ŠKODA 1203 (1968–present – small-scale custom production)

Škoda 1101–1102 “Tudor”

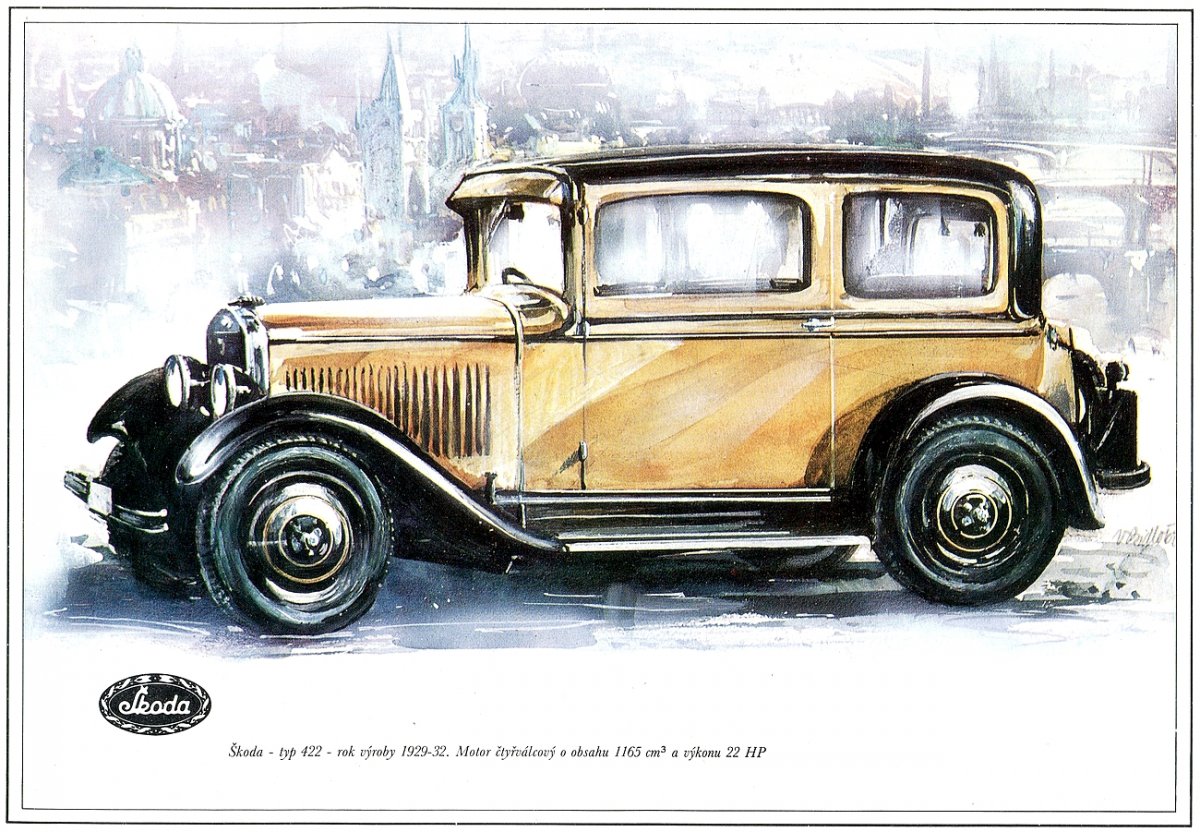

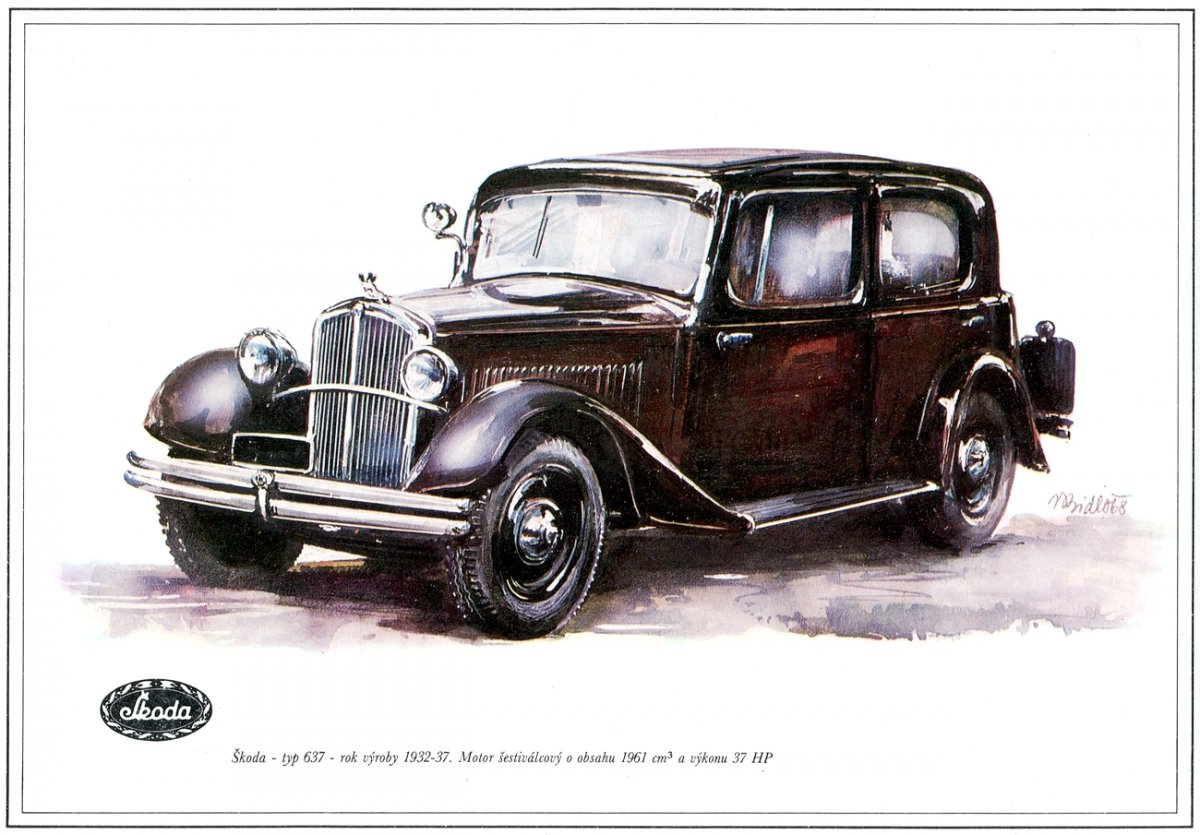

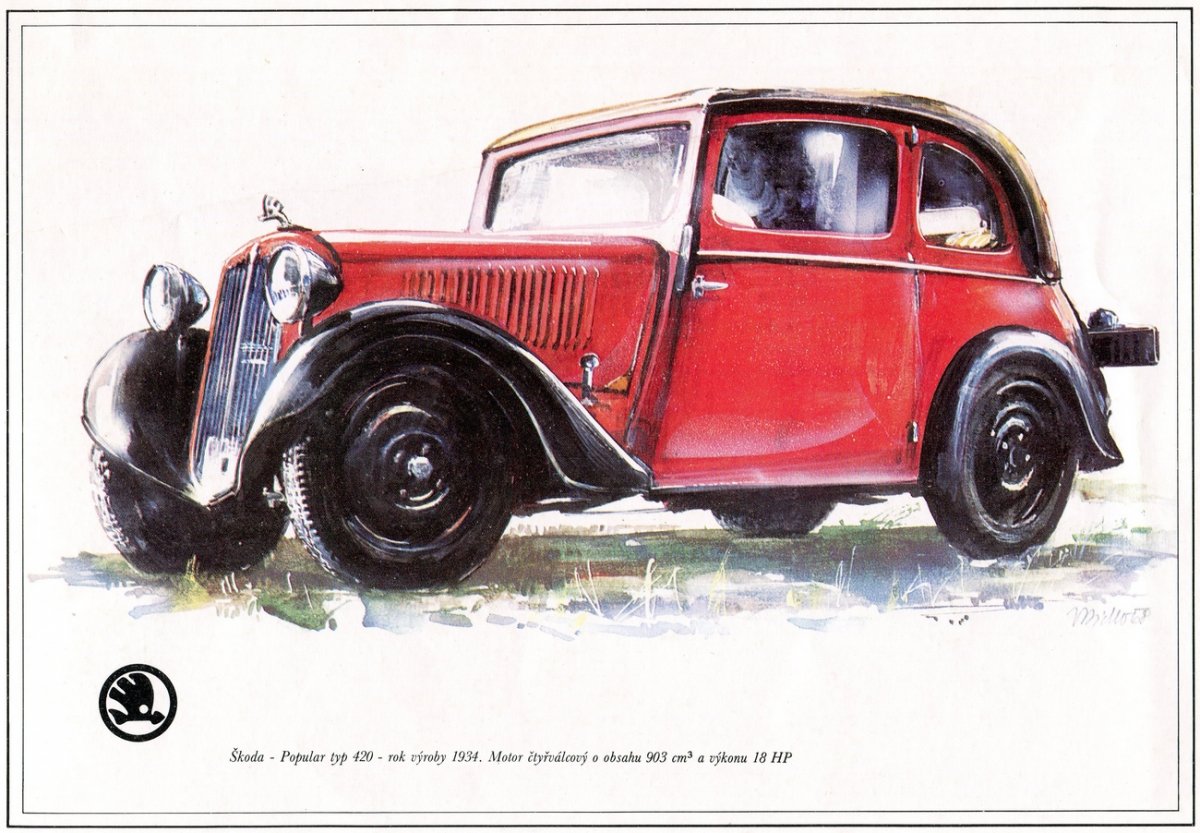

In April 1933, the Mladá Boleslav car manufacturer introduced its new model, the 420 Standard, whose design would have a career spanning 40 years. Until then, Mladá Boleslav cars had a classic ladder frame supporting robust, heavy bodies to better withstand twisting. The key innovation was a central frame welded from two longitudinal U-profiles, forked at the front to house the engine and gearbox. The differential was bolted to the rear end of the frame, and the drive shaft ran through the backbone tube. This central frame significantly reduced stress on the body structure, saving considerable weight during production. Another major innovation was the use of swing half-axles at the rear, introduced on a Škoda for the first time, while the front axle remained rigid. All pre-war Populary, Rapids, Favorits, and Superbs used a similar concept but with a central tubular frame.

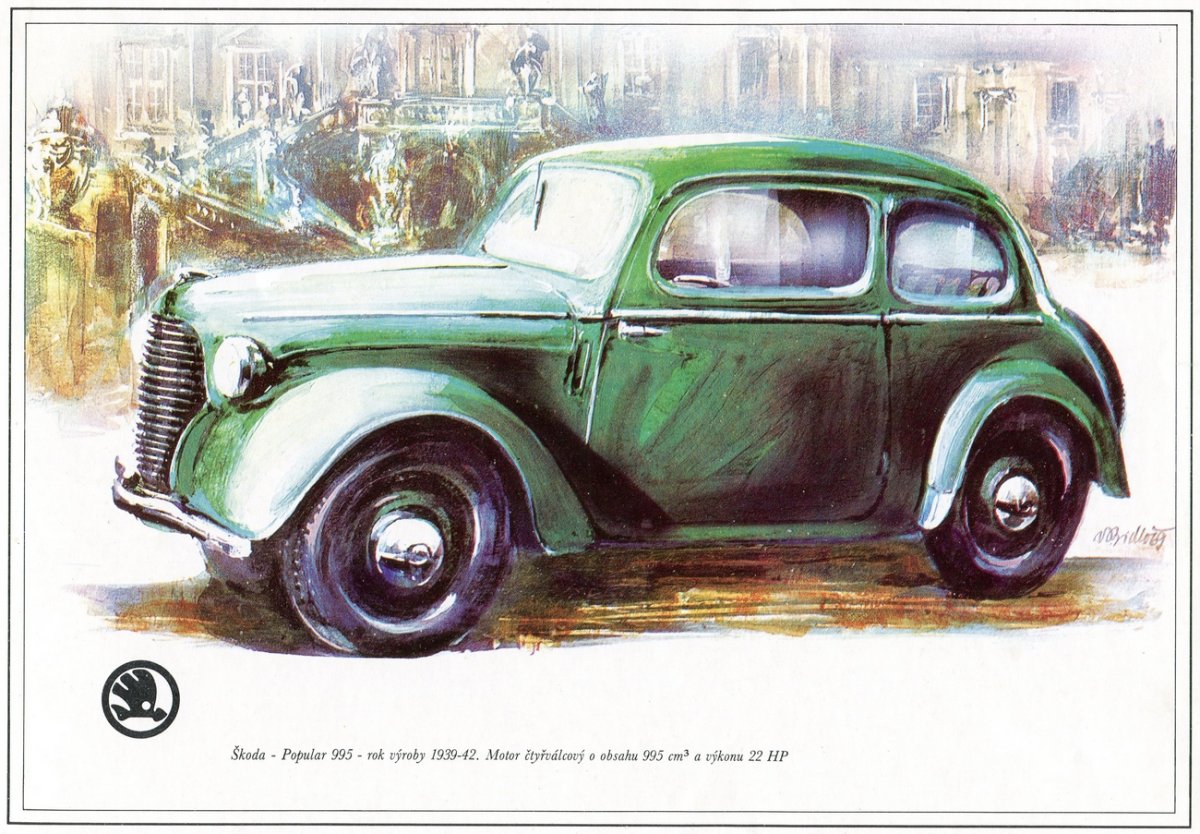

After World War II, Škoda first assembled the smallest Populary 995 from remaining stock. At the end of 1945, production began on the updated Škoda Popular 1101, launched in May 1946 with a four-seat, two-door body called Tudor. Without tires, it cost 67,700 Kč and was sold via a waiting list controlled by the Ministry of Transport. From July 1946, versions with a closed van body for a 300 kg payload (priced at 68,250 Kčs without tires) were also produced, and a four-seater convertible (68,000 Kčs) was planned. The new model featured an attractive, modern body, while its chassis design remained fundamentally unchanged. Motorists nicknamed the car “Tudor” (from “two-door”), a name that later stuck even for four-door versions. The price was quoted without tires because new ones were practically unavailable—buyers had to find their own.

In 1948, production began on the Škoda 1102, which differed mainly by having four doors and a column-mounted gearshift instead of a floor-mounted one.

Technical Data

Š 1101 = 1946–1949, 1089 cm?, 32 PS / 4600 rpm, 4-stroke 4-cylinder, D68x75 mm, 100 km/h, 8 l/100 km

Š 1102 = 1948–1952

Produced: 66,904 units

Škoda 1200, 1201, 1202

In spring 1952, Škoda introduced the 1200, a four-door, five-seat car called a sedan – the first Škoda with an all-steel body. This innovation allowed higher production volumes and partial automation using welding semi-automats. The body had elegant rounded lines, recessed door handles, a split windshield, and front-hinged doors. The larger trunk improved practicality, and 80% of the mechanical components were shared with the previous model. The engine displacement was increased, derived from the 1102’s four-cylinder.

The 1200 was also produced as a van, station wagon, and ambulance. In 1955, it was modernized and renamed Škoda 1201. The compression ratio increased from 6.6 to 7, raising power output; second gear gained synchronization. The 1201 was mainly built in utility versions — station wagon (STW), van, ambulance, and later pickup — with production gradually moving to the Vrchlabí plant.

The early 1950s were difficult for Škoda, which had to develop small military vehicles and take over production of Tatra’s small cars. Meanwhile, private car ownership was extremely rare — in 1952, only 53 private individuals in a country of 12 million could buy a car.

In 1961, Škoda introduced the mildly modernized 1202. Starting with the 1200, this model became the longest-produced Škoda with a backbone frame, remaining in production until 1973 in versions such as STW, van, ambulance, hearse, and pickup. With its discontinuation, Škoda closed the successful chapter of traditional front-engine, rear-wheel-drive cars.

Technical Data

Š 1200 = 1952–1956 – 1221 cm?, 36 PS / 4600 rpm, 4-stroke 4-cylinder, D72x75 mm, 105 km/h (95 km/h for utility versions), 9.5–10 l/100 km

Š 1201 = 1955–1961 – 1221 cm?, 45 PS / 4200 rpm, 4-stroke 4-cylinder, D72x75 mm

Š 1202 = 1961–1973 – 1221 cm?, 47 PS / 4500 rpm, 4-stroke 4-cylinder, D72x75 mm

Produced: 127,282 units

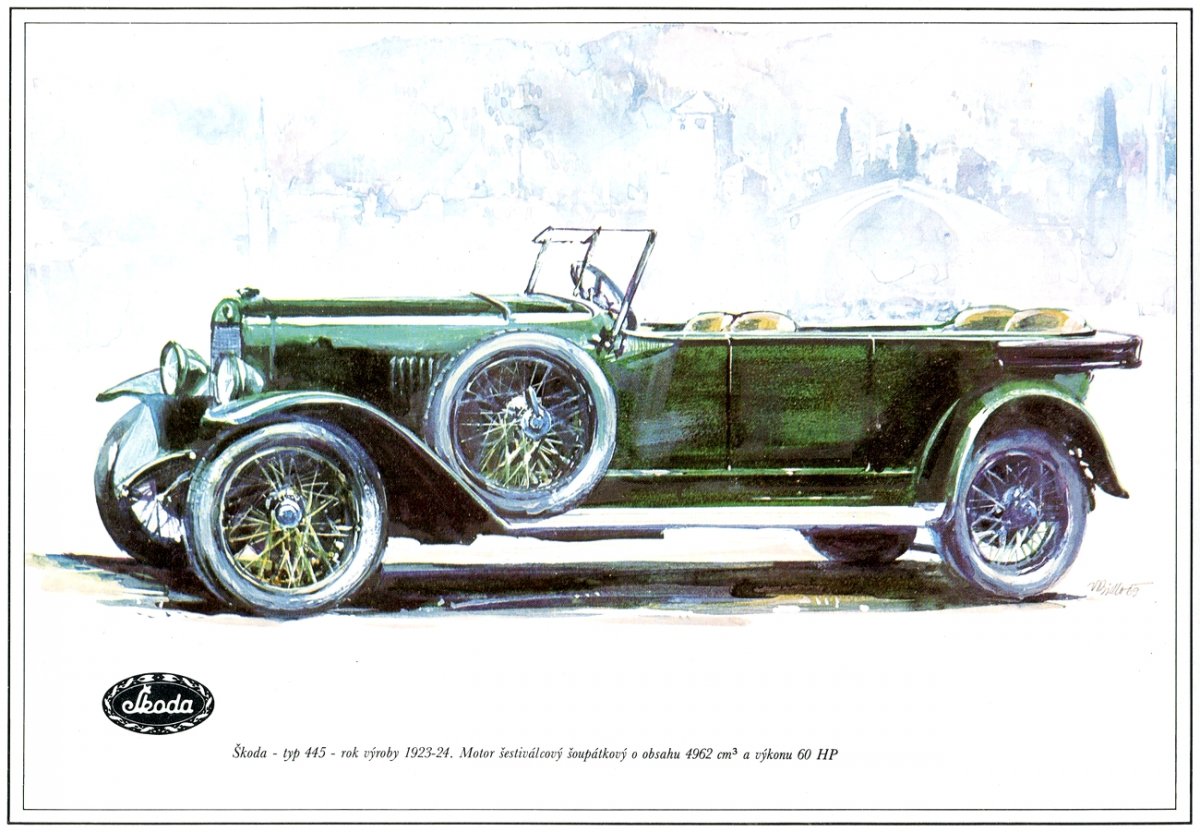

Škoda 440, 445 “Spartak”

The prototype premiered on December 19, 1953 — the 69th birthday of President Antonín Zápotocký — a common practice at the time. The car featured a completely new body and updated mechanics, introduced as a transitional “people’s car” under the revolutionary name Spartak. Production of the elegant two-door body started in 1955.

When sales began, the car was officially presented at the Brussels Motor Show under various names: Orlík, later Rival, and finally Škoda 440 (both domestically and abroad). However, everyone simply called it Spartak. The standard model cost 27,450 Kčs. The 440 engine was based on the 1101 type but had a redesigned intake manifold, a new carburetor, and output of 40 hp. In 1957, by fitting a larger 1221 cm? engine, the Škoda 445 was born.

Although originally conceived as a temporary model, it remained in production for almost ten years. Both versions were built to a high European standard and were successfully exported not only to Western Europe but also to South America and New Zealand. Buyers cared less about the political situation in the country of origin and more about the car’s technical quality, driving characteristics, and fuel efficiency — all of which were convincing.

Technical Data

Š 440 = 1955–1959 – 1089 cm?, 40 PS / 4200 rpm, 4-stroke 4-cylinder, D68x75 mm, 110 km/h, 7.7 l/100 km

Š 445 = 1957–1959 – 1221 cm?, 45 PS / 4200 rpm, 4-stroke 4-cylinder, D72x75 mm, 115 km/h, 8 l/100 km

Produced: Š 440 = 75,417 units, Š 445 = 9,375 units

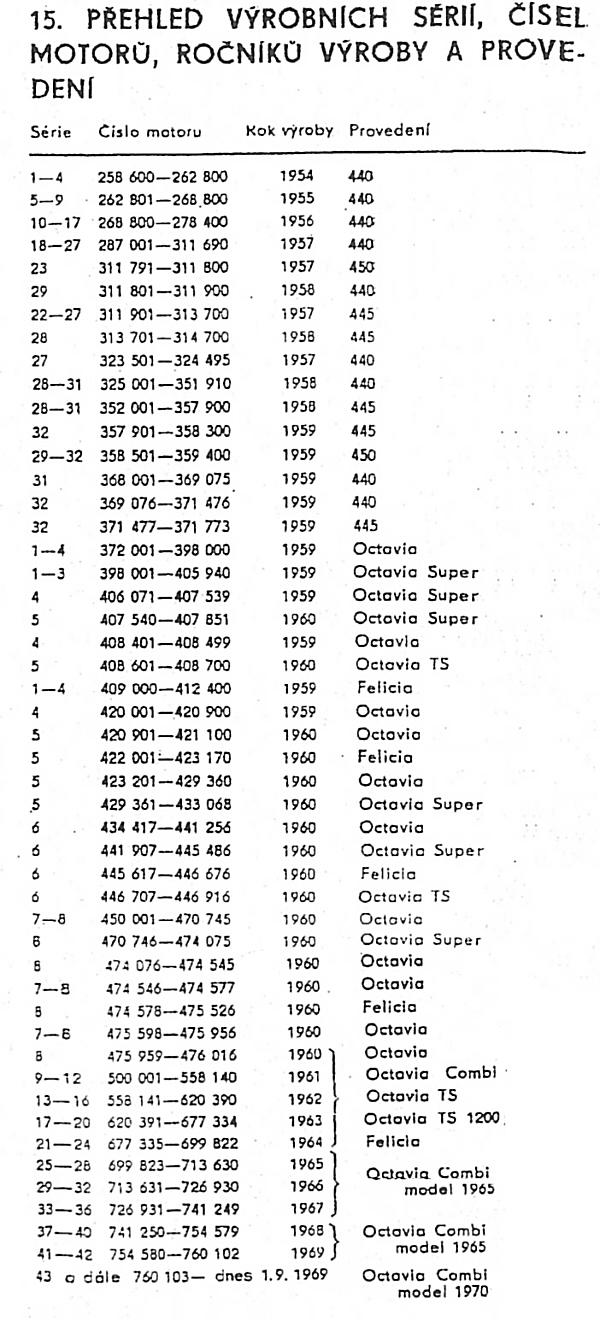

Škoda Octavia

In 1959, all Škoda passenger cars received a new front suspension, replacing the transverse leaf spring with coil springs and telescopic shock absorbers. This technical change was accompanied by a new name — Octavia — symbolizing the eighth model in the design lineage that began with the Popular 420.

Several versions appeared — in 1959, the Octavia Super and Octavia Touring Sport; later, in 1961, the Octavia 1200 Touring Sport with the largest and most powerful engine (55 hp). The final version, the Octavia Combi from 1961, was also equipped with the Super’s four-cylinder engine. Its luggage compartment featured a practical horizontally split tailgate. The Combi, after numerous updates, remained in production the longest — until 1971.

Motorists everywhere loved the Octavia for its excellent handling, especially on poor roads. The even weight distribution between the front and rear axles was exceptional for a front-engine, rear-wheel-drive car. In Chile, these Škodas were even nicknamed “jeeps,” as they handled mountain trails with ease. It was a robust, reliable car that held a leading position in its class even by the strictest standards.

The Octavia was remarkable not only for its exports but also for being assembled and adapted in various parts of the world. In New Zealand, starting in 1966, Motor Industries began small-scale production of the Škoda Trekka. Using Octavia chassis imported in CKD form, they mounted a pickup body with a 500 kg payload, ideal for farmers. The vehicle proved exceptionally durable and forgiving of rough treatment. On request, it could be fitted with a locally produced limited-slip differential that significantly improved off-road performance. Buyers also appreciated the fiberglass superstructure and tarpaulin option.

From 1971, Trekka vehicles were even exported in CKD form to Indonesia, where they were assembled in new workshops in Surabaya. In Pakistan, Haroon Industries began importing Octavia chassis in 1968 to produce the Skopak (Škoda–Pakistan–Karachi). Fiberglass panels were mounted on a metal frame to create a lightweight vehicle with a 500 kg payload. Versions included a doorless and roofless pickup, a standard pickup with drop-down sides, an STW with a fiberglass body, an open airport vehicle for luggage and passenger transport, a delivery van for bottles, a taxi, and even a four-seat coupé.

Technical Data

Octavia = 1959–1964 – 1089 cm?, 40 PS / 4200 rpm, 110 km/h, 4-stroke 4-cylinder, D68x75 mm, 7.7–9.5 l/100 km

Octavia Super = 1959–1964 – 1221 cm?, 45 PS / 4200 rpm, 115 km/h, 4-stroke 4-cylinder, D72x75 mm

Octavia TS = 1961–1964 – 1089 cm?, 50 PS / 5500 rpm, 120 km/h, 4-stroke 4-cylinder, D68x75 mm

Octavia TS 1200 = 1962–1964 – 1221 cm?, 53 PS / 5100 rpm, 128 km/h, 4-stroke 4-cylinder, D72x75 mm

Octavia Combi = 1961–1971 – various models 1961–1970, 1221 cm?, 47–51 PS, up to 120 km/h, 4-stroke 4-cylinder, D72x75 mm

Produced: Octavia – 229,531 units; Octavia Super – 79,489 units; Octavia TS + 1200 TS – 2,273 units; Octavia Combi – 54,086 units

Škoda 450 – Felicia

The 1.1-liter engine didn’t remain unchanged — with further refinements and especially the addition of twin carburetors, its output rose to 50 hp. In 1958, a sporty 2+2 convertible body was developed for this engine — the Škoda 450. This beautifully styled and highly successful car was built at the Kvasiny plant. Even after more than forty years, its elegant lines have lost none of their charm. Few European mass-produced cars of the time could match the 450 in its category.

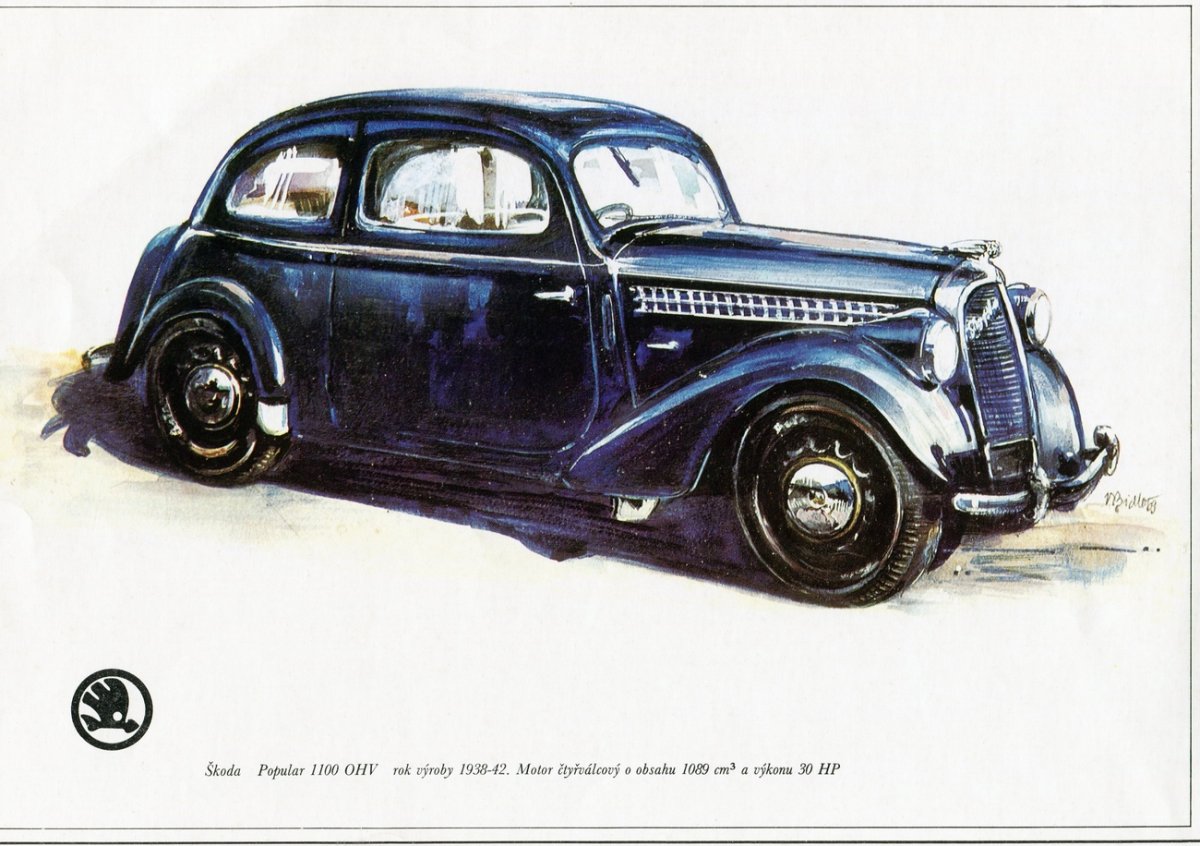

Similarly to the Octavia, a new name — Felicia — appeared after the adoption of coil springs and telescopic shock absorbers on the front suspension, replacing the leaf springs. The name derives from the Latin felicitas, meaning “happiness.” The car’s proven 1.1-liter engine originated from the 1938 Popular 1100 OHV four-cylinder. Though now featuring an aluminum block, it remained essentially the same brilliant design — so good, in fact, that it continued to power the utility Škoda 1203 for decades.

In 1961, the Felicia received a larger 1.2-liter engine and the name Škoda Felicia Super. A great idea was the option of a detachable hardtop alongside the folding fabric roof. The hardtop not only enhanced the car’s appearance but also made driving much more comfortable in cold weather.

Technical Data

Š 450 = 1957–1959 – 1221 cm?, 50 PS / 5500 rpm, 4-stroke 4-cylinder, D72x75 mm, 128 km/h, 9 l/100 km

Š Felicia = 1959–1964 – 1089 cm?, 50 PS / 5500 rpm, 4-stroke 4-cylinder, D68x75 mm, 128 km/h, 9 l/100 km

Š Felicia Super = 1961–1964 – 1221 cm?, 55 PS / 5100 rpm, 4-stroke 4-cylinder, D72x75 mm, 130 km/h, 9.5 l/100 km

Produced: 15,873 units

Škoda 1000 MB

Based on experience with various prototypes and after evaluating production feasibility, Škoda decided that the next car would have “everything in the back.” The new OHV four-cylinder engine became one of the most advanced one-liter engines in Europe, representing state-of-the-art technology for its time.

It was produced using pressure die-casting of aluminum — a method with a long tradition in Czechoslovakia, dating back to a 1922 patent. Škoda had used aluminum engines since the 1950s, but these were cast using conventional techniques. For the new car’s large and complex engine block, a special die-casting line had to be built directly in the factory. This line produced 59 different components, including both halves of the gearbox casing. It was no small feat, especially since no one in Mladá Boleslav had prior experience with pressure die-casting.

This was a highly modern technology that allowed for thinner wall sections, better material efficiency, and lower energy consumption. It also made it possible to cast in certain components, such as steel threaded inserts, directly into the mold. The engine block for the new rear-engine car was developed at the end of the 1950s and became the foundation for all Škoda production engines for the next 40 years. The mold was created by the Italian company Fonderpress from Bologna, while the production technology was handled by Škoda. The result was a casting weighing 10.5 kg, which after machining weighed only 9.6 kg.

In Europe, this casting method was new, and Škoda’s foundry ranked among the most modern of its time — only the Iron Curtain and Czechoslovakia’s poor international image prevented it from receiving the recognition it deserved.

The bodywork for the new car underwent significant development. The first prototype appeared in early 1959, incorporating all design requirements to date. By 1960, further refinements led to a prototype so close to the final design that it was given the name Favorit, under which it was expected to debut. Between 1963 and 1964, the final version was adjusted to match suppliers’ capabilities so the car could be ready for production.

Developing the body required half a million work hours, not counting testing. Fifty prototypes covered millions of kilometers in all conditions — from the Azerbaijani desert in summer, to Moscow winters, to East German motorways throughout the year. No other Škoda car had ever received such extensive development attention.

Octavia owners were surprised by the new four-seat, four-door monocoque body, completely unlike anything previously built in Mladá Boleslav. It featured a front luggage compartment with a separate space for the spare wheel and a fuel tank with the filler neck in the right front fender. Behind the split rear seatbacks was another storage space, with the battery located beneath on the left side.

When the car appeared in mid-1964, international automotive magazines praised it highly. Tests confirmed that Škoda had created one of the best one-liter cars of its era, featuring an exceptionally modern layout. Instead of Favorit, the car was ultimately named Škoda 1000 MB.

Building a new factory for this model represented a huge leap forward for Mladá Boleslav — comparable only to the expansion of the 1920s, when modern technology was first introduced. The difference this time was that a small plant grew into a large industrial complex. Constructing and equipping the production halls — from the engine plant to the body shop — became a valuable training ground for an entire generation of engineers, significantly advancing both practical and theoretical knowledge.

The factory, whose construction began in 1960, was completed in 1964 and became one of the most modern automotive plants in Europe. Covering an area of 800,000 m?, its daily output increased from 120 Octavias to 600 new “Embéčko” cars.

The body of the new car required 8,000 spot welds. Surface treatment was also completely new — the underbody was phosphated, the entire body was dipped, and soundproofing and insulating materials were applied using advanced methods. Painting was performed in an electrostatic field. The assembly lines and facilities were equipped with 11 kilometers of overhead conveyors. A total of 300 supplier companies contributed to the construction and equipment of the plant.

Technical Data

Š 1000 MB = 1964–1969 – 988 cm?, 4-stroke 4-cylinder, D68x68 mm, 42 PS / 4650 rpm, 120 km/h, 7–8 l/100 km

Š 1100 MB de Luxe = 1967–1969 – 1107 cm?, 4-stroke 4-cylinder, D72x68 mm, 52 PS / 5200 rpm, 127 km/h, 7–8 l/100 km

Produced: 1000 cm? – 419,540 units; 1100 cm? – 23,601 units

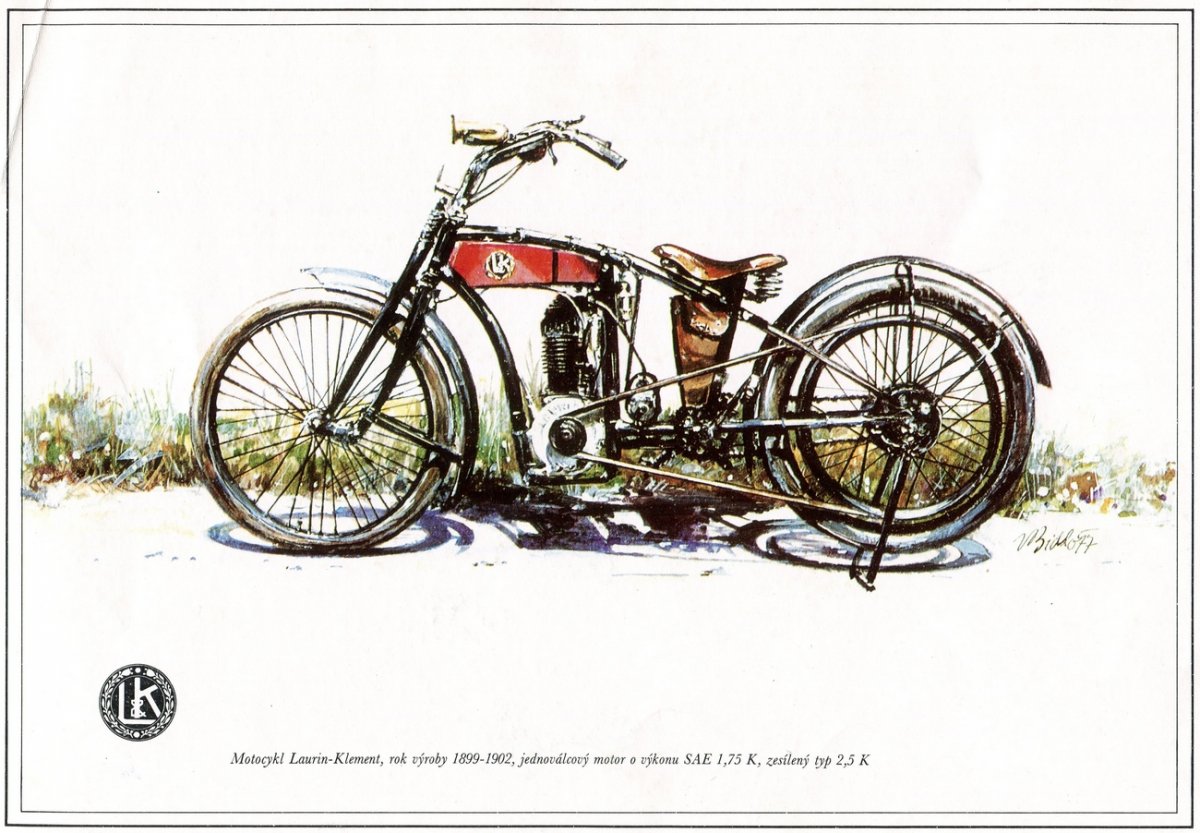

Slavia 1895–1905 – bicycles and motorcycles produced in the Mladá Boleslav workshop under the Slavia brand. The bicycle with linden leaves symbolized Slavic nations and bore the names of founders Laurin & Klement.

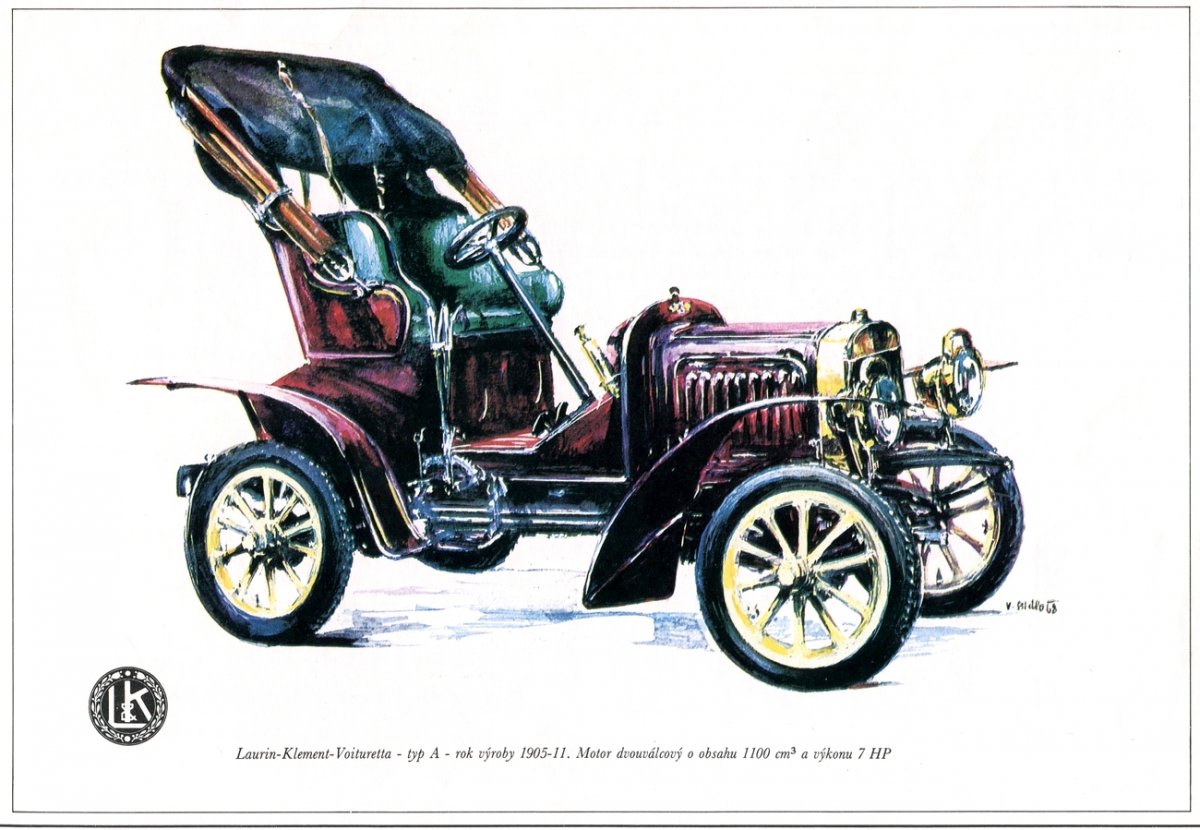

L&K 1905–1925 – an Art Nouveau-style logo from the early 20th century. The founders’ initials are surrounded by a laurel wreath symbolizing victory and glory – a prelude to the success of Laurin & Klement.

Škoda 1926–1933 – since 1926, cars in Mladá Boleslav were produced under the Škoda brand. The logo continued the oval shape and laurel motif of the previous brand.